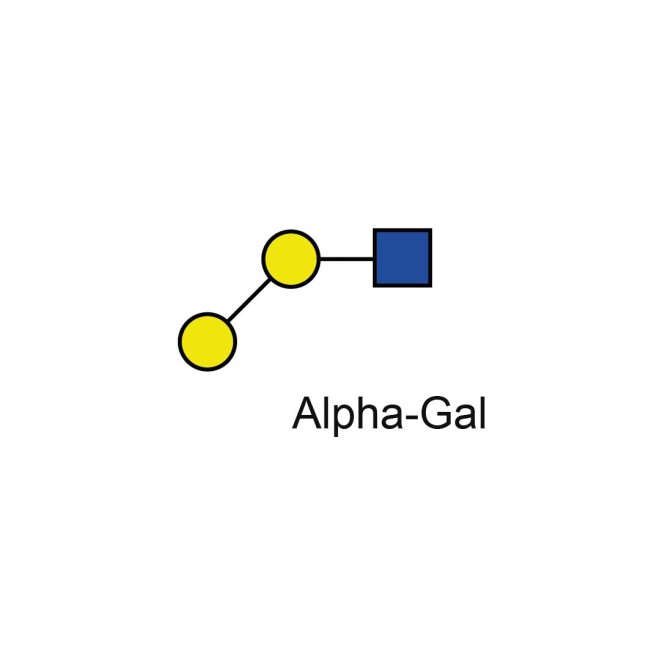

Alpha-Gal standard (unlabelled)

References

Platts-Mills TA, Schuyler AJ, Tripathi A, Commins SP. Anaphylaxis to the carbohydrate side chain alpha-gal. Immunol Allergy Clin North Am 35:247-260. (2015)

Tharmalingam T, Adamczyk B, Doherty MA, Royle L, Rudd PM. Strategies for the profiling, characterisation and detailed structural analysis of N-linked oligosaccharides. Glycoconj J. 30:137-146 (2013)

Kozak RP, Tortosa CB, Fernandes DL, Spencer DI. Comparison of procainamide and 2-aminobenzamide labeling for profiling and identification of glycans by liquid chromatography with fluorescence detection coupled to electrospray ionization-mass spectrometry. Anal Biochem 486:38-40 (2015)

Gal alpha 1-3 Gal beta 1-4 GlcNAc, Truncated N-Glycan trisaccharide containing alpha-gal epitope, Alpha Gal glycan is a linear trisaccharide.

m/z: 546.2 g/mol

View product documentation:

Product Specification

The native Alpha Gal glycan is a linear trisaccharide with sequence linkages Gal-alpha(1-3)-Gal-beta(1-4)-GlcNAc. This standard was developed as a positive control when using alpha galactosidase for biopharmaceutical glycoprofiling assays.

2-AA and 2-AB labeled versions of this Alpha Gal standard are also available.

Galactose-alpha-1,3-galactose, commonly known as alpha gal, is a carbohydrate found in mammalian meat products. Approximately 1% of immunoglobulins in humans are specific to alpha-gal, and these antibodies (anti- Gal) cause an allergic reaction. Due to its potential immunogenicity, it is important therefore to screen biopharmaceuticals for alpha-gal. Some drug developers are also investigating the use of anti-Gal for tumour therapies.

Molecular Weight: 546.2 g/mol

Purity: 86.5% pure as assessed by and HPLC.

Sources: Chemically synthetized,

Form: Dry. Dried by centrifugal evaporation from an aqueous solution.

Storage: -20˚C both before and after dissolution. This product is stable for at least 5 years as supplied.

Shipping: The product can be shipped at ambient when dry. After dissolution, ship on dry ice.

Handling: Allow the unopened vial to reach ambient temperature and tap unopened on a solid surface to ensure that most of the lyophilized material is at the bottom of the vial. Gently remove the cap, add the desired volume of reconstitution medium, re-cap and mix thoroughly to bring all the oligosaccharide into solution. For maximal recovery of oligosaccharide, ensure that the cap lining is also rinsed and centrifuge the reconstituted vial briefly before use. Ensure that any glass, plasticware or solvents used are free of glycosidases and environmental carbohydrates. Minimise exposure to elevated temperatures or extremes of pH. High temperatures and low pH will cause desialylation. High pH will cause epimerisation of the reducing terminus GlcNAc.

Safety: This product is non-hazardous and has been purified from natural sources certified to be free of all hazardous material including pathogenic biological agents.

-660x660.jpg)