Mix of 6 quantitative monosaccharide standards

Mix of 6 quantitative monosaccharide standards

- Product Code: CM-MONOMIX-10X3

- Size 10 nmol of each, pack of 3

- £893

A quantitative mix of six monosaccharides: glucosamine – galactosamine – galactose – mannose – glucose/dextrose – fucose

10 nmols of each monosaccharide per vial. 10nmols of each, pack of 3

CM-MONOMIX-10X3 – 3vial

This component is also part of our LudgerTag Quantitative Monosaccharide Release and 2-AA (2-aminobenzoic acid) Labelling Kit (LT-MONO-96)

Product specification

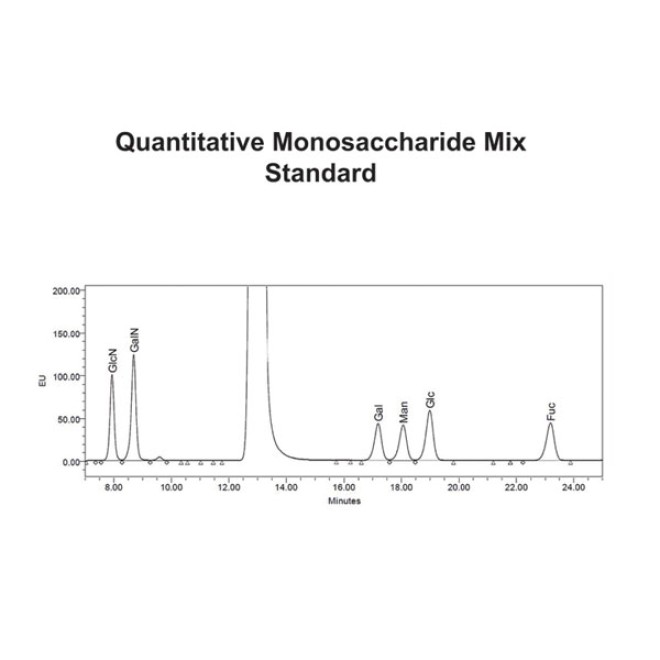

The monosaccharide standard is a quantitative standard comprised of a mixture NIST-F and USP traceable monosaccharides including glucosamine (GlcN), galactosamine (GalN), galactose (Gal), mannose (Man), glucose/dextrose (Glc) and fucose (Fuc).

The monomix standard enables instrument calibration in order to quantitatively determine the monosaccharide components in your glycoprotein. We recommend a five point calibration curve to be used for the monomix standard. Information on how to do this is explained in the Monosaccharide Analysis Kit documentation.

HPLC Analysis of the Monosaccharide Standards

HPLC analysis of 2-AA labeled monosaccharides is a robust method for determining monosaccharide levels in your glycoprotein sample. There are some important issues that need to be understood to enable effective data interpretation.

1. Each monosaccharide has a different fluorescence yield per nmol. A standard curve of monosaccharide concentration versus fluorescence needs to be determined.

2. Free dye is not removed from the samples after 2-AA labeling to ensure no monosaccharides are lost in a dye clean-up stage. Free dye elutes as a large off-scale peak at about 15 minutes and also several large peaks after 28 minutes.

3. N-acetylglucosamine and N-acetylgalactosamine are both de-N-acetylated during the acid hydrolysis step of this process to produce glucosamine and galactosamine respectively.

4. Glucosamine is subject to an approximate 4 % epimerisation resulting in mannosamine. Mannosamine elutes immediately before the galactosamine peak, with no baseline resolution.

5. Galactosamine also produces an epimer peak, typically smaller than 2 %. However this epimer peak often elutes with the free dye peak.

6. The use of xylose as an internal standard allows samples to be compared directly. This allows compensation for any pipetting/sample preparation errors that may have occurred during sample processing.

7. Sample stability – we recommend keeping labeled samples in the freezer at -20 °C if you intend to store them for longer than one week.

Form: Dry. Dried by centrifugal evaporation from an aqueous solution.

Amount: 10 nmol each of 6 monosaccharide standards

Storage: -20˚C both before and after dissolution. This product is stable for at least 5 years as supplied.

Shipping: The monosacchride standards can be shipped at ambient when dry. After dissolution, ship on dry ice.

Handling: Allow the unopened vial to reach ambient temperature and tap unopened on a solid surface to ensure that most of the lyophilized material is at the bottom of the vial. Gently remove the cap, add the desired volume of reconstitution medium, re-cap and mix thoroughly to bring all the oligosaccharide into solution. For maximal recovery of oligosaccharide, ensure that the cap lining is also rinsed and centrifuge the reconstituted vial briefly before use. Ensure that any glass, plasticware or solvents used are free of glycosidases and environmental carbohydrates. Minimise exposure to elevated temperatures or extremes of pH. High temperatures and low pH will cause desialylation. High pH will cause epimerisation of the reducing terminus GlcNAc.

Safety: This product is non-hazardous and has been purified from natural sources certified to be free of all hazardous material including pathogenic biological agents.