2-AB glycan labelling kit (2PB reductant)

![]() 2-AB (2-aminobenzamide) is one of the most widely used fluorescent labels for glycosylation analysis. The LudgerTag 2-AB labelling Kit includes all the reagents required to label up to 30 glycan samples.

2-AB (2-aminobenzamide) is one of the most widely used fluorescent labels for glycosylation analysis. The LudgerTag 2-AB labelling Kit includes all the reagents required to label up to 30 glycan samples.

Two kits are available, which differ in the type of reductant supplied: sodium cyanoborohydride or non-toxic 2-picoline borane.

Product Specifications

Application: For labelling of free glycans with 2-aminobenzamide acid (2-AB).

Description: The kit contains reagents for the conjugation of dye to the free-reducing end of the glycan by a reductive amination reaction.

Traditional 2-AA and 2-AB labelling kits use sodium cyanoborohydride as a reducing agent during glycan labelling. This reagent is toxic so a fume cupboard should be used during handling. To conform with emerging health and safety regulations we are now replacing these with our new VP glycan kits that use picoline borane which is a significantly safer reductant.

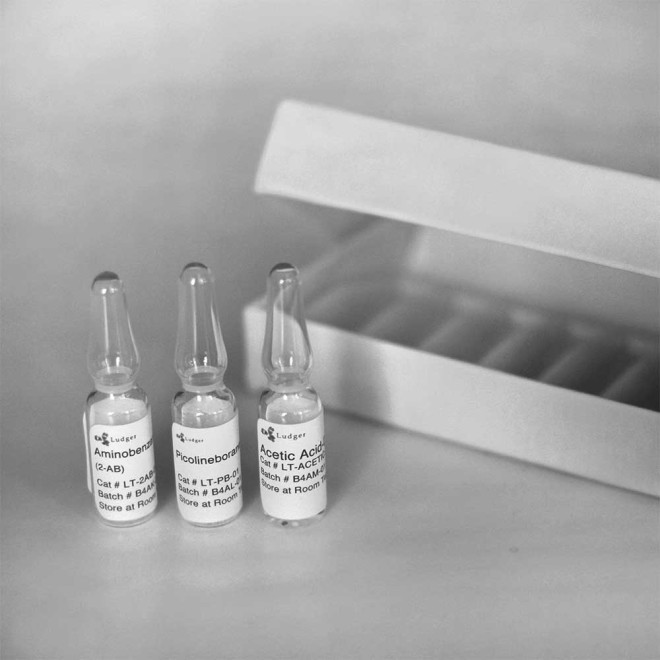

The 2-AB labelling kit contains two sets of the following reagents (15 samples each) supplied in glass ampoules sealed under pure nitrogen:

LT-KAB-VP24

2-Aminobenzamide (2-AB dye)

Dimethyl sulfoxide (DMSO) / Acetic acid solution

2-picoline borane

LT-KAB-A2

2-Aminobenzamide (2-AB dye)

Dimethyl sulfoxide (DMSO)

Acetic acid

Sodium cyanoborohydride

Number of Samples One 2-AB labelling kit contains reagents to label up to 30 separate analytical samples per kit

Dye purity >99% by HPLC

Molecular weight 136.15

Lambda-ex 250 nm

Lambda-em 428 nm

Amount of Sample From 25 pmol up to 25 nmol glycans per sample.

Suitable Samples Any purified glycans with free reducing termini can be labeled.

Structural Integrity No detectable (< 2 mole per cent) loss of sialic acid, fucose, sulfate, or phosphate.

Labeling Efficiency Typically > 85 % (dependent on sample).

Labelling Selectivity Essentially stoichiometric labelling.

Protocol

1. Purify the glycan: LudgerClean EB10 cartridges (LC-EB10-A6) have been designed for the purification of glycans from proteins, salts, and detergents.

2. Transfer sample to reaction vial: The amount of sample should be in the range of 100 picomoles – 50 nanomoles for a glycan pool obtained from a typical glycoprotein. With a single pure glycan, as little as 5 picomoles can be labelled and detected in subsequent HPLC analysis. Suitable reaction vials include small polypropylene microcentrifuge tubes and tubes for PCR work.

3. Dry the samples: Dry down the samples if the volume of the sample exceeds 10 μL.

If the samples need to be dried down then this should be done using a centrifugal evaporator. If this is not possible then freeze drying (lyophilization) can be used with caution (in particular, ensure that the sample dries to a small, compact mass at the very bottom of the vial). Do not subject samples to high temperatures (>28°C) or extremes of pH as these conditions will result in acid-catalysed loss of sialic acids (high temperatures, low pH) or epimerization of the glycan-reducing terminus (at high pH).

Once the samples are dry then redissolve the glycans in 10 μL of water.

4. (LT-KAB-A2 only) Prepare a DMSO-acetic acid mixture: Add 150 μL glacial acetic acid to the vial of DMSO and mix by pipette action.

5. Add the dye: Add the DMSO-acetic acid mixture to a vial of the 2-AB (2-Aminobenzamide Acid) dye and mix until the dye is dissolved.

6. Add the reductant: Add the dissolved dye to a vial of sodium cyanoborohydride or picoline borane and mix by pipette action until the reductant is completely dissolved to make the final labelling reagent.

7. Add labelling reagent to samples: Add labelling reagent to each dried glycan sample, cap the microtube, and mix thoroughly.

8. Incubate: Place the reaction vials in a heating block, sand tray, or dry oven set at 65°C and incubate for 3 hours. In most cases, the incubation time can be shortened to 2 hours or extended up to 4 hours without significantly changing the outcome of the labelling reaction.

9. Centrifuge and cool: After the incubation period remove the samples, centrifuge the microtubes briefly, then allow them to cool completely to room temperature.

10. Sample Cleanup: Post-labeling sample cleanup is recommended to remove excess dye and other labelling reagents.

Product overview

Product overview